Prior to colonial settlement, wetlands and marshes lined our coastal and freshwater shorelines, providing a land-water habitat connection, dissipating wave energy, and slowing erosion of nearshore land. Since land in urban areas is often unavailable or difficult to restore to pre-settlement times, floating wetlands (FWs), an ecologically engineered technology, represent an effort to mimmick the wetlands that existed long ago. FWs hold the promise of returning ecological services like pollutant uptake and transformation, water quality improvement, wave attenuation, habitat, and aesthetic beautification.

Various prototypes are being tested in locations around the world. A “Biohaven” technology designed by Floating Island International, for example, consists of recycled PET plastic mesh and buoyant marine foam. In Biohabitats’ Bio-flotsam FW, buoyant plastic bottles removed from the polluted water body, are sandwiched media that is retained within two frames of wood and plastic mesh. This design was constructed and deployed by volunteers in Baltimore’s Inner Harbor as part of the Baltimore Healthy Harbor Initiative. Biohabitats patented this design to keep the system open-source for nonprofits and other grassroots watershed groups to use. Other Biohabitats projects where FWs have been deployed or studied include Jamaica Bay, NY near Long Island, NY, Potomac Yards in Washington, DC, and the Town of Orleans, MA.

Student volunteers plant floating wetlands along Baltimore’s Inner Harbor

Oyster/mussel reefs

Oysters are a type of shellfish that live in brackish and saltwater bays, estuaries, and tidal creeks. Oysters are filter feeders, filtering all the nutrients they need directly from the water in their environment. A single oyster can filter up to 50 gallons of water each day as reported by The Nature Conservancy, effectively cleaning the water by obtaining their nourishment from the free-floating plankton. This promotes the growth of underwater grasses, such as wild celery, which serve as important habitat for other species. In addition, oyster beds form large, complex structures where many aquatic species hunt for food and hide from predators.

Spat set on oyster ball ready to be deployed at Gerritsen Creek

Oysters once thrived in Jamaica Bay. Due to overharvesting and other human disturbances, self-sustaining oyster populations are no longer found. In October 2010, Biohabitats installed an oyster bed off Dubos Point in Queens and 12 oyster reef balls in Gerritsen Creek in Brooklyn. The oyster bed was constructed with spat-on-shell to mimic a small reef off the shores of Dubos Point, while the reef balls, previously set with spat, were placed just off shore in Gerritsen Creek. You may ask, what is spat? When oysters reproduce, they spawn tiny larvae that freely navigate the water column until they find an appropriate habitat with an adequate surface to attach. Once the larvae permanently attach to a surface, they are known as spat.

Three years of comprehensive monitoring and ongoing annual monitoring suggest that the oysters are not only able to survive, but reproduce, improve water quality, and enhance the ecology of the Bay. Laboratory testing also indicated that the oysters were relatively disease-free.

Another saltwater mollusk, the ribbed mussel, can also filter substantial amounts of water. In 2011, several artificial substrates for the growth of ribbed mussels were constructed within Fresh Creek Park in Brooklyn. The sites were monitored for mussel growth, substrate condition, and water quality. The primary goals were to test the effectiveness of ribbed mussels in removing nutrient and particulate organic matter from a CSO discharge.

Green bulkheads

The term ‘green bulkheads’ comes primarily from ongoing efforts in the Cuyahoga River in Cleveland, Ohio to provide supportive habitat features for larval and juvenile fish during spawning and development season. These features are attached to existing shoreline stabilization structures along the river – like steel bulkheads. The reason for this effort is that the first 4.5 miles upstream from Lake Erie has been highly altered to accommodate navigation & shipping activities, but has become less able to support developing aquatic life.

Recently, Biohabitats completed a project with the Cuyahoga County Planning Commission (CCPC) designing, installing and evaluating hexagonal steel casing structures attached to existing bulkheads filled with various habitat-supporting materials such as bioballs, sticks and brushes. Six-month testing showed that all designs accumulated a biomass layer and small organism attachment and proved durable within the channel. The overall project was successful in its ability to experiment with different insert materials. The CCPC has since transferred ownership of the installed habitats to Cuyahoga River Restoration. This nonprofit currently has several types of habitat configurations represented and monitored in several hundred units deployed throughout the ship channel!

ECOncrete enhanced sea wall green bulkhead. Image courtesy of ECOncrete® Tech Ltd.

In coastal marine applications, a coastal bulkhead is more commonly referred to as a sea wall. ECOncrete®, a marine ecological concrete technology company based in Tel-Aviv, Israel, supplies a range of modular enhanced sea wall elements, which integrate into existing infrastructure. ECOncrete® has developed a way to manipulate the surface properties of concrete to support growth of various marine plants and animals. The properties can be tailored to induce growth of specific targeted species. This image shows a mock-up of an ecologically enhanced sea wall or another iteration of ‘green bulkhead’ in coastal marine systems.

Algal turf scrubbers® (ATS™)

Algal turf scrubbers® (ATS™) are a patented water treatment technology developed by Dr. Walter Adey of the Smithsonian Institution and licensed to HydroMentia, Inc. that use the natural abilities of algae, bacteria and phytoplankton. The device is designed to promote the growth of beneficial algae, which filter nutrients from impaired or polluted water that is pumped into a constructed flow-way.

The system consists of an attached algal community growing on screens in a shallow trough or raceway through which water is pumped in a manner that mimics a controlled stream ecosystem. The algal community provides water treatment by uptake of inorganic compounds through photosynthesis. Nutrients are removed from the waterway through biomass storage of the algae growing on the screens and periodic harvesting of the grown algae. The harvested algae may be used as a source material for a variety of uses, including biofuel, compost or concrete production.

Attached algal “turf” pulls nutrients and traps sediment from inflow while pumping dissolved oxygen into outflow

Biohabitats and the University of Maryland constructed a pilot-scale ATS™ system in 2011 along Baltimore’s Inner Harbor to determine how effective this technology is in partially addressing the city’s nutrient reduction goals and in supplying oxygen to receiving waters to prevent or ameliorate fish kills during low oxygen events. Preliminary results demonstrate the feasibility of using ATS™ systems for both objectives.

Living shorelines

Hardened shorelines refer to shorelines stabilized with steel and/or concrete structures such as bulkheads, revetments, seawalls and breakwaters. These features remove the ability of the shoreline to carry out natural processes, provide little habitat for aquatic species and ironically, may increase the rate of shoreline erosion on unprotected areas. Living shoreline refers to a more natural bank stabilization technique, using native plants, sand and limited use of rock to provide shoreline protection and maintain valuable habitat. These features are created by human design, engineering and construction to mimic natural shoreline processes. Living shoreline projects utilize a variety of structural and organic materials, such as wetland plants, submerged aquatic vegetation, oyster reefs, coir fiber logs, wood, sand fill and stone. While a living shoreline will still stabilize the shoreline, it will also provide the following ecosystem services: protect the surrounding riparian and intertidal environment, improve water quality via filtration of upland run-off and create habitat for both aquatic and terrestrial species.

The U.S. Army Corps of Engineers, NOAA, and a community of practice called SAGE, or a Systems Approach to Geomorphic Engineering, have created a brochure detailing the use of both green and gray shoreline stabilization techniques to improve social, economic and ecosystem resilience.

Examples of Biohabitats living shoreline projects include Leonardtown Wharf, in which Biohabitats designed tidal wetlands to both improve the existing degraded shoreline and to connect to existing wetlands. Biohabitats replaced a deteriorating bulkhead with a living shoreline in the Nereid Shoreline Stabilization project. Last but certainly not least, Biohabitats restored two acres of coastal wetland habitat in Freshkills Park-North Park in New York City and included a living shoreline to assist with rising sea levels as well as dissipate wave energy, stabilize the shoreline and create aquatic habitat. The park was credited with protecting nearby Staten Island neighborhoods from severe flooding during Hurricane Sandy.

Living breakwaters & Pile encapsulation.

Living breakwaters are structures placed parallel to the shore in medium to high energy open water environments to dissipate wave energy while providing habitat and erosion control. These breakwaters are typically constructed with rock and potentially seeded with oyster spat. Oysters biogenically build and layer over time to create a calcified natural surface atop the man-made structure. This growth can enhance strength, stability and longevity of the breakwaters.

Breakwaters do not keep the water out, however, they calm water, reduce wave heights, and reduce shoreline erosion. Living breakwaters create calm areas near the shoreline, which can be replanted with submerged aquatic vegetation and marsh grasses to create intertidal and marsh habitat for aquatic organisms. Breakwaters can also be designed and located to encourage or discourage sedimentation along the shoreline. Sedimentation can help to extend the beach, useful in areas of high erosion. Sedimentation is not desirable close to critical habitat or navigation channels.

Living breakwaters can provide habitat throughout the water column. The subtidal structure underwater can incorporate small scale pockets, or reef streets, into the breakwater to provide foraging and shelter for juvenile fish. Above water, breakwaters can host harbor seals and nesting birds in upland islands.

ECOncrete ecological armoring unit.

The NYC Rebuild by Design Living Breakwaters proposal for the Hurricane Sandy Design Competition includes multiple techniques, such as reef streets, oyster gardens to spat-on ECOncrete® ecological armoring units. ECOncrete® ecological armoring units are modular building blocks of marine infrastructure, which provide coastal defense against hydrodynamic forces of sea waves. ECOncrete® armoring units are designed to create urban marine habitats, which encourage growth of various marine organisms by modifying the composition, texture and design of standard armoring units.

ECOncrete® ecological pile encapsulation substitutes standard concrete pile encapsulation. Piles are used in piers and jetties. It is applied to protect steel piles or repair timber piles from deterioration by marine burrowers such as worms and mussels. In addition to the necessary constructive support and protection, ecological pile encapsulation creates a new and productive habitat for marine plants and animals.

Biohut®

Biohut® is a constructed marine fish habitat, which replicates the ecological function of a shallow water nursery (rocks, sand and submerged aquatic vegetation) in places where it has been damaged by human activity and built infrastructure including harbors, pipelines and seawalls. Biohut® is developed by Ecocean, an innovative company based in Montpellier, France that specializes in developing and implementing radical new technologies for the sustainable use and management of the marine environment. Biohut® is most simply, a double caged system filled with recycled material that provides shelter and food to increase the survival rate of fish larvae. Product offerings depend on the location of the Biohut®, i.e. Port Biohut®, Shoreline Biohut®, Breakwater Biohut®, Mooring Biohut® and Pipe Biohut®.

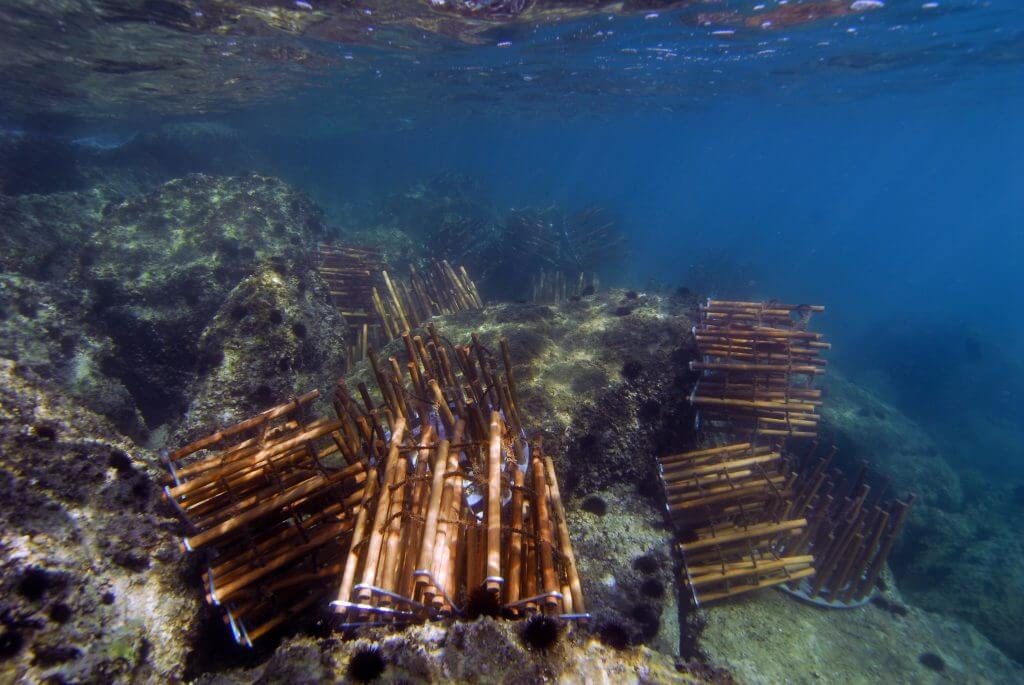

Port Biohut ©Ecocean

The image of the Breakwater Biohut® shows bundles of wooden sticks of variable length with coconut fiber strands bound around the bundles, nested at variable height on a perforated metal plate and fixed by shallow drilling of the stone surface.

Breakwater Biohut ©Ecocean

The Mooring Biohut® is still going through technical improvements and environmental assessments, but consists of a wooden artificial habitat in the form of a “hoop net.” Its height and width are adjustable and the hut is fixed along mooring lines already in place. The Pipe Biohut® is in the prototype phase and consists of a flexible metal plate with fixed sticks of wood of varying heights that is secured to the outside of pipe without drilling.

Innovative trash collection

How do we clean up trash from our waterways? There are a variety of technologies and solutions that people from all over the world have designed.

In Baltimore, Mr. Trash Wheel, designed by Clearwater Mills for the Waterfront Partnership of Baltimore is a unique trash collection device that picks up litter and debris from the Jones Falls River. The river’s current provides power to turn a water wheel, which lifts debris from the water and deposits it into a dumpster barge. When there isn’t enough water current, a solar panel array provides additional power to keep the wheel turning. When the dumpster is full, it’s towed away by boat, and a new dumpster is put in place. At peak operation, the $700,000 contraption can remove 50,000 pounds of trash in one day. You can watch Mr. Trash Wheel’s live feed here.

Baltimore’s “Mr. Trash Wheel”

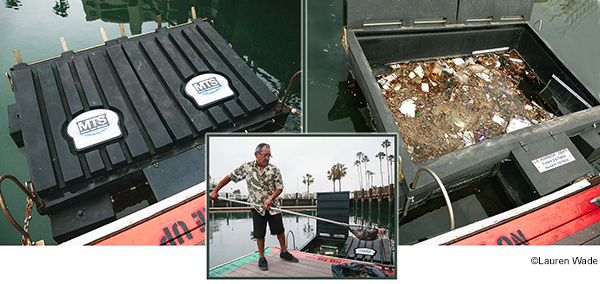

On the west coast, Louis Pazos has installed enough Marina Trash Skimmers to collect 500,291 gallons of debris to date. The Marina Trash Skimmer looks like a dumpster semi-submerged in water fastened to the side of a dock or marina. It is equipped with a pump that circulates water through its filter system, cleaning 300 gallons of water a minute by gently sucking in and trapping debris inside. Typical materials collected include Styrofoam, cans and containers, plastic bags and wrappers, free-floating organic material (FOM) and even oil if an oil pad is included. Basic skimmers start at $9600.

Marine Trash Skimmer ©Lauren Wade

The Ocean Cleanup Project was founded in 2013 by then 18-year-old Boyan Slat. Now, Slat and his team of 70+ scientists, engineers and communications professionals claim they can clean up half the plastic in the Great Pacific Garbage Patch in a decade. The plan is outlined in a 530-page feasibility report. While the project has seen its share of criticism, it has received $2.2 million in crowdfunding money from more than 38,000 backers, making it the most successful campaign of its kind in history. The plan includes placing more than 62 miles of floating barriers in the middle of the patch. The barriers will passively corral floating plastics as wind and ocean currents push them toward a central collection platform that will sort and process the items. Boats will pick up the recovered plastics every few weeks, and the hope is that they can be recycled or used as fuel back on land. The team is currently testing scaled-down prototypes in the North Sea off the Netherlands coast to test the barriers’ durability in a variety of weather conditions.

©Seabin Project

Similar to the Marina Trash Skimmer, The Seabin Project, a product developed by Australians Andrew Turton and Pete Ceglinski, is an automated trash bin that can attach to marinas & yacht club docks, ports or any calm water body. The Seabin uses the elements of a pool skimmer: water flows in from the top and is pumped through a filter on the bottom, capturing debris, oil, fuel and detergent. The pump is a small submersible water pump underneath the Seabin that uses either 110V or 220V. The pump energy consumption is around $1 USD per day. Turton and Ceglinski are now on their fifth version of the product, priced at around $3,300 per unit, in which they have been able to use recycled plastic in the Seabin itself. The mesh in the catch bag is also made from recycled plastic. Sales start this summer, and the team is currently trialing recycled HDPE ocean plastics in the design, meaning that once the products are capturing plastic in the marinas, they can (in theory) be turned into more Seabins. A percentage of oil can also be captured with oil adsorption technology adapted custom for the catch bag. The team also hopes to further develop this technology to increase capture percentage.