The world is waking up to the power of natural systems to help solve pressing challenges related to biodiversity loss, climate change, water pollution, and environmental injustice, but the practice of creating and deploying nature-based solutions is still relatively nascent compared to the design and construction of grey infrastructure.

Nature-based solutions transformed a former golf course into an ecological preserve that provides habitat, manages stormwater, and reconnects people to nature. Acacia Reservation – Design-Build, Lyndhurst, OH ©David Ike Photography

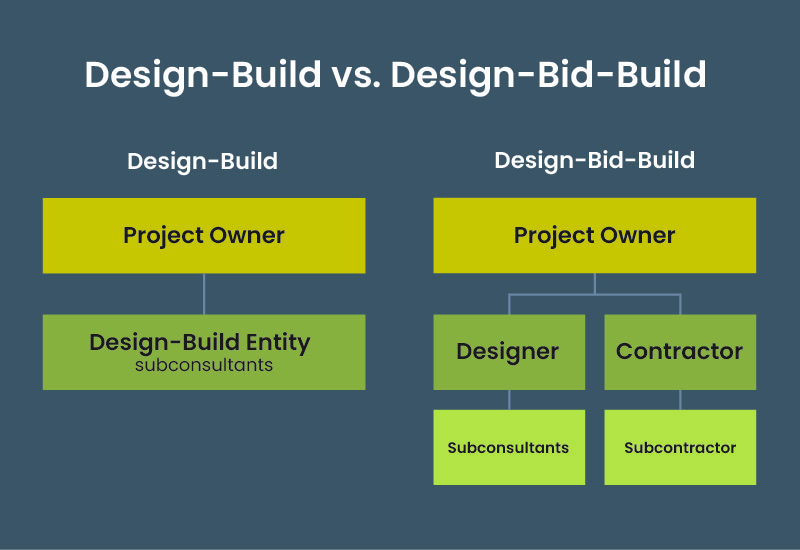

Creating a nature-based solution is a journey, and there are countless decision points along the way—from selecting the best way to study the problem you’re trying to solve to determining monitoring and maintenance protocols to ensure your solution is lasting. One of the most important decisions, however, is made before any work begins: how to deliver the project. The delivery method defines the characteristics of how a project is designed and constructed and details the responsibilities of the parties involved, including the owner, designer, and contractor. The delivery method you choose can impact every aspect of the project, including how it is contracted, organized, managed, and executed…and who assumes the risk if something goes awry. Unfortunately, many project owners, managers, funders, and practitioners may not know that they have a choice when it comes to project delivery, or they may be unaware of the benefits offered by a very promising alternative.

Projects that harness the power of ecology to address human challenges—such as stream and wetland restoration to improve water quality or living shorelines to buffer vulnerable coastal communities—are most commonly executed using the traditional design-bid-build method.

The Design-Bid-Build Process

With design-bid-build, the project owner first has to contract a designer to create the project design, prepare drawings and specifications, manage the permitting process, and possibly provide some level of bidding and construction phase support. To do this, the project owner starts by soliciting proposals from design firms by issuing a Request for Proposals (RFP). In some cases, the selection process may be executed in three steps: first, issuing a Request for Qualifications to identify qualified candidates; next, sending selected candidates an RFP to solicit proposals; and third, interviewing the top selected firms to make a final selection. The project owner then contracts the selected firm to develop the design. Once it is final, design documents are put out to bid. Contractors review the documents, ask clarifying questions, consult with any necessary suppliers and subcontractors, and submit their best price for constructing the project. The project owner reviews each submitted bid, sometimes with the support of the designer, and typically selects the contractor with the lowest bid price for the project. Finally, the project owner hires that contractor using a separate contract.

While this phased, linear project delivery method has been well-tested, it is not without drawbacks.

With design-bid-build, the project owner has to develop two or more sets of bid documents and then manage two separate procurement processes— and two separate contracts. This takes extra time, energy, and resources from the project owner. Once the design contract is awarded, the project owner must work with the designer and manage the design phase. Likewise, once the construction contract is awarded, the project owner has to manage the construction contract as well as any construction phase scope given to the designer. As the entity issuing these contracts, the project owner is the main point of contact and must facilitate all communication between the separately contracted designer and contractor. This includes facilitating the submittal process, managing the schedule, reviewing two invoices every month, and attending to any Requests for Information that may arise. Some project owners may elect to hire a third-party construction management firm to act as their representative and handle these duties, but this scenario adds additional procurement effort and contract management for the project owner.

There is also the issue of quality. Some project owners may be required by procurement regulations to select the construction bid with the lowest price, and low price does not mean high quality. In fact, low bid selection often puts knowledgeable and experienced contractors at a disadvantage. Far too often, the lowest bidding contractor fails to accurately capture all aspects of the project work in their bid, which can lead to shortcuts, lower quality work, and project setbacks.

The design-bid-build project delivery model can also expose the project owner to risk. When a project is put out for construction bid, the project owner implies a warranty such that the plans and specifications are complete and sufficient to build the project. The contractor has to follow those plans and specifications and they are not responsible for the consequences of any defects they may contain. The project owner bears this responsibility—even if the contract includes language requiring the contractor to visit the site, review the plans, and familiarize themselves with the project requirements. There are several examples of case law to support this, including Spearin v. United States, Hollerbach v. United States, and others. Ultimately, this can make the project owner liable for change orders that arise from issues with the plans and specifications. This implied warranty emphasizes the need to prescriptively detail all elements of the project. To do this, advanced design milestones are needed, which can drive up the cost of the project design. Because of the linear nature of design-bid-build, all of this is done by the designer with no input from the contractor that will be building the project.

Budget is also a concern. All project owners have a budget and design-bid-build projects that are selected based on the lowest bid can be appealing. But there are also costs associated with the procurement and management of multiple contracts, and low-bid construction can lead to headaches, as site conditions and issues with plans and specifications can lead to change orders that the project owner is typically responsible for. When all is said and done, the design-bid-build project delivery method is often not as cost-effective as it initially appears and involves a lot of time and effort on the part of the project owner. Many project owners find themselves questioning this process and wondering…

What other options exist when it comes to delivering projects involving nature-based solutions?

Many choices exist for common construction projects, but when it comes to projects that require working with dynamic, natural systems, an ideal option is design-build project delivery.

The Design-Build Process

Design-build is a blended process that combines design and construction services under one contract. The project owner hires a design-builder (or a design-build team consisting of a design firm and a construction company) to handle the entire project from start to finish. Unlike the linear, fragmented design-bid-build process, design-build is integrated, as the designer and constructor collaborate throughout every stage of the project.

How is this better for the project? Having the designer and construction contractor under a single contract allows for direct communication between the parties. At each design milestone, the experience and input of the construction contractor can be leveraged to vet and value engineer design elements. With the construction contractor’s early involvement, the project can be designed to a budget, with the designer and contractor continuously validating project pricing. This allows the design-build team to provide the project owner with cost assurances and often, a guaranteed maximum price for the work. Ecological construction specialists are at the design table, helping to ensure the project’s constructability and value, and ecological designers remain involved as the project is built, helping to increase efficiency and ensure project goals are achieved.

A design-build team can be led by the designer or the contractor. In a contractor-led scenario, the designer handles project design, permitting, and—depending on the contractor’s direction and the project budget—construction oversight and inspection. When the team is designer-led, the designer will hire the construction contractor. This scenario allows the designer more control over the construction phase oversight and inspection. Regardless of who leads the team, a major benefit of design-build is the direct and open communication it affords the designer and contractor throughout the project since they are working under the same contract.

Designers and contractors problem solve during a design-build project

One relatively new application of design-build delivery is a stepped or progressive process known as “Progressive Design-Build” (PDB). With PDB, cost and schedule are not established as part of the selection process, and the team is selected primarily on qualifications. The owner and project team “progress” toward a price, and the work is completed in two phases: Phase One includes budget-level design and preconstruction services, and Phase Two final design, construction, and commissioning.

Advantages of Design-Build

Risk Reduction

For project owners, one of the most appealing aspects of the design-build delivery method is the reduction of risk. With design-build, the liability that is carried by the project owner in a design-bid-build model shifts to the design-builder. This shift occurs because the design-builder develops the project design, eliminating the project owner’s implied warranty, and is responsible for delivering a finished project.

Ease of Process

Another benefit of design-build is its turnkey nature. The design-builder is responsible for permitting and delivering the entire project, so the amount of time and budget a project owner might otherwise spend on construction management and inspection can be reduced. Add to that the elimination of a construction bidding phase and those time and budget reductions become even greater. With design-build, the project owner has a single point of contact for all stages of work. This not only streamlines communication and saves time; it relieves the project owner from having to manage any disputes, questions, communication, and miscommunication that may arise between the contractor and the designer. As stated in the Design-Build Association of America’s most recent Design-Build Data Sourcebook, “While single-source contracting is the fundamental difference between design-build and the old ways, equally important is the culture of collaboration inherent in design-build which means fewer headaches, formalities, and paperwork.”

Biohabitats principal engineer, Mike Lighthiser, climbs aboard a loader to collaborate with a design-build teammate from Budhoe’s Backhoe on a wetland restoration project in Fort Collins, CO.

Budget + Time Savings

Cost savings can be associated with many of the other benefits that come with the streamlined approach of design-build. As mentioned earlier, design-build allows for iterative cost estimating during the design phase. This means cost guarantees can be provided earlier in the process to help align the design and construction with the budget to avoid overruns. However, design-build requires that the project owner have funding for design and construction. While this can seem more costly up front, it locks in pricing early, avoids market cost increases, and eliminates the need to bid and manage separate design and construction contracts.

©Here Today Photography

The ongoing communication between the designer and builder—intrinsic to quality design-build—also helps ensure that the entire project team is not only aware of the project owner’s schedule, but primed and ready to begin construction when the permitting process is complete. This, like so many other aspects of design-build, enables the project owner to avoid gaps and pauses between stages of the project, saving time and ensuring funding deadlines are met.

Design-build team members from Biohabitats and EQR ground truth the 30% design at and LID retrofit project site in Washington, DC.

Time savings, like budget reductions, go hand in hand with many of the benefits of the design-build delivery method. This is true beyond the world of ecological restoration, green infrastructure, and nature-based solutions. In fact, research from the Construction Industry Institute and the Charles Pankow Foundation shows that from design through completion, design-build projects are delivered 102% faster than traditional design-bid-build. Project goals are maintained while mutually agreeable scope changes achieve the required performance and maintain the overall budget. Design-build also enables construction value engineering to identify schedule efficiencies early on and incorporate them into the design.

A Biohabitats design-build project along the Chesapeake Bay uses nature-based solutions, including reef balls, large trees with intact roots, to replenish and protect eroding beaches. The design-build team included ER&M and Sustainable Science Shoreline Design.

Quality, Innovation + Flexibility

Design-build projects can deliver higher quality outcomes. That quality begins with procurement, as design-build proposals should be scored by best value, rather than lowest bid. Quality continues at the design table. Having the contractor participate in design means the project owner gets value engineering that can improve the design. Quality is a theme that continues throughout all phases of a design-build project, including construction. Designer-led design-build in particular allows the designer control to oversee and inspect the construction and ensure the intent of the design is met.

A Biohabitats engineer is able to provide guidance during stream restoration construction in CO.

The design-build delivery method also brings the advantage of flexibility, which is important for two reasons. First, it allows the project owner’s vision to be achieved through performance-based criteria and goals, rather than the overly prescriptive plans and specifications often associated with design-bid-build efforts. This can eliminate the need for advanced design milestones and the costs and delays that can come with them. Second, the flexibility of design-build affords the team the freedom to adapt to changing field conditions and creatively–and quickly—problem-solve when unexpected surprises arise during construction. With natural, dynamic systems, adaptability can be essential for success. The ability to adapt and collaborate during construction saves time and money.

Nature-based solutions delivered via design-build helped restore degraded headwaters of Spa Creek in Annapolis, MD

So why isn’t everyone choosing to use the design-build for nature-based solutions?

For many, the barrier comes in the form of procurement regulations. Even though design-build is the fastest-growing delivery method in the US, it is not an option for many government agencies due to state and local procurement policies. In many cases, those policies are nearly one hundred years old. In North Dakota and Iowa, for example, no public agencies are authorized to use design-build. In Louisiana, only the state’s Department of Transportation and public airports have full authority to use it, while some other entities may use it only under certain conditions, such as if the project involves constructing or repairing certain school buildings damaged by Hurricanes Katrina or Rita. Meanwhile, any public agency in Indiana, Colorado, and Montana may use design-build project delivery.

Given the urgent need for environmental progress, why are so many states so strict about the use of design-build? “It is a complicated problem that doesn’t have one clear answer,” says Grade Edinger, Procurement Strategy Lead for the Environmental Policy Innovation Center, (EPIC) a nonprofit “think and do” tank focused on policy change and innovation to speed and scale up environmental and public health progress. One of EPIC’s core strategies is “Eliminating the Organizational Barriers That Prevent Public Agencies From Adapting to 21st Century Solutions” and they recognize procurement policy as one of such barrier.

“like turning a cruise ship…”

Projects implemented by public entities involve taxpayer dollars, so it is not surprising that procurement laws are often scrutinized to ensure those dollars are spent responsibly and equitably. “All this attention leads procurement officers to be fairly conservative,” says Edinger. “State and federal government are huge, with tons of people and opinions. There are many obstacles in the way of change, including the attitudes of long-time agency staffers who may be reluctant to try something new.” For those reasons, Edinger says, changing procurement law can be “like turning a cruise ship.”

But that is not stopping EPIC, and industry organizations like the Design-Build Institute of America (DBIA), from working with communities to make change happen.

“We see state, local, and federal agencies tie themselves up in red tape around the procurement aspect of ecological restoration projects,“ said Edinger. “We work to untangle some of that red tape to help benefit the contractors doing the work, the community getting the benefits of the work, and the government agencies who are paying for the work.”

That untangling can involve anything from a “policy scan” where they review statutes to help communities understand if alternative procurement methods would be legal, to testifying before legislators or helping them to draft legislation. EPIC is working to integrate new data and technology into this work to further improve the way communities can show how alternatives to the design-bid-build delivery method can responsibly steward taxpayer dollars. Their efforts, like those of DBIA, are working.

“Over the last three years, we’ve seen a huge interest from state and federal government in changing procurement to better work for ecological restoration,” said Edinger. “We have seen states introduce and pass laws related to the use of alternative procurement tools or begin exploring areas where they may be able to do some pilot work.”

That includes laws specific to design-build. DBIA works in all 50 states and the nation’s capital to ensure legislative leaders understand the value delivered by design-build, and they have sponsored or supported legislation that has improved access to the delivery method. (See Nonprofit Spotlight: DBIA for more information).

For other project owners, funding may be a barrier to design-build. A project owner may, for example, only have available funding for design, or they may need a complete design in order to procure funding for construction. There has been some progress, however, toward removing some barriers to alternative project delivery methods imposed by grant funding requirements. EPIC, for example, works with state and federal agencies throughout the country to assess feasibility, and design environmental programs that utilize alternative procurement tools.

Some barriers may not be barriers at all, but rather misperceptions. Through its outreach, education, and certification program, DBIA is helping to dispel many of the myths and fears related to design-build. (For example, see this DBIA blog post.)

Thanks to organizations like DBIA, EPIC, and others, and to the owners, agencies, firms, contractors, and communities behind a growing body of successful design-build projects, the obstacles to design-build are being dismantled. And when it comes to working with living, dynamic systems into create nature-based solutions for the many challenges we face are likely to face in the future, any remaining barriers to design-build are far outnumbered by the benefits.

A nature-based design-build restoration project regenerated stability, habitat, and function along Stickney Creek in Brooklyn, OH

Other Options

While design-build is a highly advantageous alternative to design-bid-build, it is not the only option. There are other choices available. While they are still relatively new in terms of their application to projects involving nature-based solutions, these collaborative project delivery methods may also hold promise as alternatives to the traditional design-bid-build model.

Construction Manager at Risk (CMAR): The project owner separately contracts a Construction Manager who serves as the general contractor on the project from start to finish. The Construction Manager must deliver the project within a guaranteed maximum price. The current challenge to using CMAR for projects involving nature-based solutions is finding someone with deep knowledge and experience in design and construction within dynamic, natural systems.

Integrated Project Delivery (IPD): integrates people, systems, business structures, and practices into a process that collaboratively harnesses the talents and insights of all participants to optimize results, increase value to the owner, reduce waste and maximize efficiency through all phases of design, fabrication and construction. IPD teams can include members beyond the owner, designer, and contractor. All parties are on a single contract and risk is shared equally among all project stakeholders.

Pay for Success/Performance: contract defines the expected outcomes (in the form of detailed metrics) of a private company’s work and payment for services is dependent upon project performance. The company funds the project and is only reimbursed if the project is successfully implemented and yields the agreed upon outcomes.

Public-Private Partnership: A private company and government entity collaborate on a project.